The conveyor belt offers variable speed. A digital temperature controller maintains the temperature within the predetermined range for the use of different types of shrink films such as PE, PVC, Cryovac, Clysar and other polyolefins.

A system of forced hot air circulation ensures a uniform temperature distribution, ensuring excellent film shrinkage of the whole surface, giving to the product a very good packaging presentation. Our particular design of direct heating chamber Shrink, coupled with an appropriate thermal insulation, provide a very high energy efficiency, and minimizing heat loss to the environment achieving rapid commissioning of the equipment.

ABQ Food / Beverage / Chemical Line: II-C

Shrink Tunnel II-C

Our shrink Tunnels are the result of a long experience with an elaborated design. Ruggedly built, equipped with quality materials, machines are operation´s reliable, long life and low maintenance cost.

Outstanding Features

- Structure made of carbon steel and profiled sheet and attached double etched by electric arc welding.

- Anti-corrosion treatment and finishing with polyurethane lacquer or epoxy.

- Standard motors with protection IP54 / IP55.

- Centralized panel with all the controls, signaling and regulatory control.

- Cabinet fitted with electrical elements for actuation and protection.

- Conveyor wire mesh, gimbal with galvanic coating or teflon coated conveyor with variable speed roller up to 10 m / min.

- Heating elements reinforced, finned, aluminum metallized, located in two side benches inside the chamber thermal contraction.

- Internal turbine of recirculation of hot air, high performance, built in aluminum alloy and electronically balanced.

- Digital electronic temperature control.

- High Performance Thermal Insulation.

- In and out of the tunnel with curtains impregnated glass fiber with silicone elastomer.

- Variable pitch fan for cooling the bulk and the conveyor.

- command voltage: 24 V AC.

- Supply Voltage (*) : 3x380 V + N (50 +60 Hz).

- Height adjustable work.

Actual Dimensions

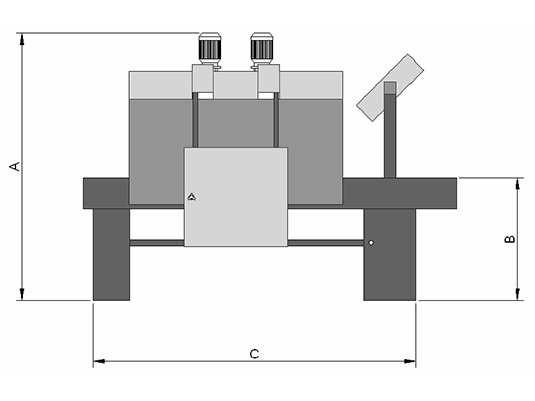

Side Layout

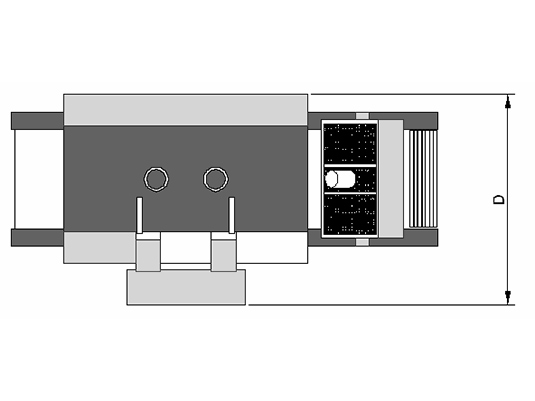

Upper Layout

Technical Data

| Model | 604 IIC | 704 IIC | 804 IIC |

|---|---|---|---|

| A (mm) | 1745 | 1745 | 1745 |

| B (mm) | 800 (1) | 800 (1) | 800 (1) |

| C (mm) | 2445 | 2445 | 2445 |

| D (mm) | 1200 | 1300 | 1400 |

| Pack (mm ) - Height x Width (Max) | 520 x 350 | 620 x 350 | 720 x 350 |

| Installed power (Kw) | 26 | 26 | 26 |

| Heating power (Kw) | 24 | 24 | 24 |

|

(1) Adjustable height between 780 and 880mm Capacity: up to 40 packages per minute depending on the size of them and the thickness and type of film used. The above features are subject to change without notice if the Company deems it because of materials or workmanship. |

|||