The machine counts with an anti-accident structure formed by a carbon steel bedplate, protected with powder electrostatic painting and coated with stainless steel AISI 304. Above the bedplate, high transparency polycarbonate allows an excellent vision of the process and an easy access to the different parts of the machine, at the same time that it protects the equipment and the operator.

Two endless screws at the main conveyor sides carry out the entry of products to the labelling area. They center, guide and separate the entering containers before being taken by the upper stabilization belt, which immobilized laterally the containers for a precise labelling.

The labelling heads are in charge of dispensing self-adhesive labels to the containers. The machine has two labelling heads arranged one after the other in order to label the front or the back of the product, according to the customer requirements. This heads work in a “Non-stop” regime, that is, when the label roll in one of them finishes, automatically it stops, and the other head begins to work, while an alarm appears on screen alerting the operator to change the exhausted roll.

ABQ Food / Beverage / Chemical Line: SOB-300

Labelling machine for the application of self-adhesive labels on oval and flat-face containers SOB-300

Has been projected and built to place self-adhesive labels on the front and the back of ovals or flat-face containers. It is equipped with a “Non-stop” labelling system, allowing a continuous labelling without stopping the equipment for the replacement of label rolls.

Details Gallery

Labeling heads for front and back of containers

NON-STOP system that avoids stopping the equipment to change the rolls in the labelling heads

Control panel via touch screen HMI 7 "full color

Outstanding Features

- PLC control system with 7” touchscreen, providing an easy operation of the machine.

- Non-stop labelling system, allowing the labelling of products without stopping to replace label rolls.

- Container spacer formed by two endless screws.

- Storage of mechanical and digitals setting for different products size.

- Main conveyor made of carbon steel and equipped with a sanitary modular chain.

- Anti-accident structure of high transparency, providing protection for the equipment and the operator.

- Label sensors, ensuring a correct labelling.

- Adequate safety systems when the machine is operating.

- Operating speed adjustable with a single parameter, maintaining the synchronism of the entire machine.

- Quality control in accordance to the guidelines of GAMP 5 (ISPE) and CFR 21 parte 11 (FDA).

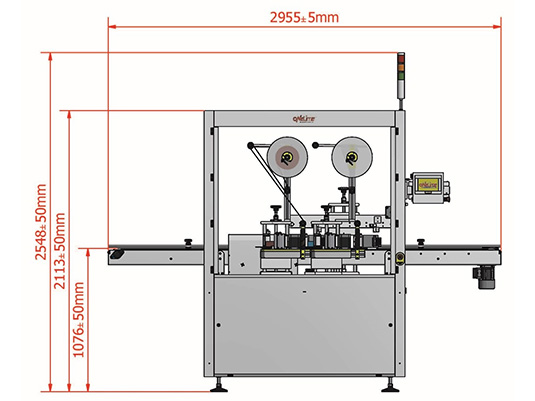

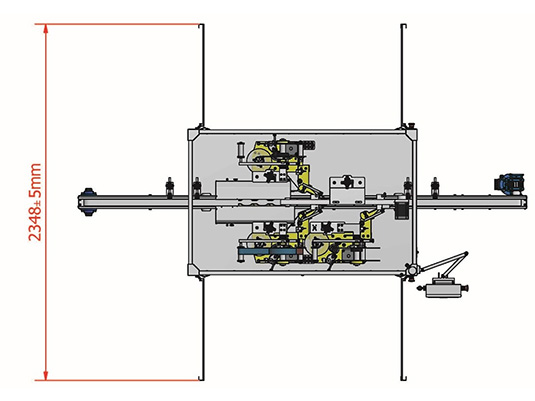

Actual Dimensions

Side Layout

Upper Layout

Technical Data

| Dimensions (mm) - Lenght x Width x Height | 2955 x 963 x 2548 |

| Weight (kg) | 600 |

| installed Power (KVA) | 2 |

| Noise Level (dB (A)) | ≤ 70 |

| Production capacity (units/hour) | Up to 12.000 |

| Admisible labels (mm) - Height x Width | 80 x 55 |