The ARII-80 NON-STOP labeling head is a device designed to apply self-adhesive labels with NON-STOP function, reducing the idle time in production line due to stopping of the labeling head to replenish the labels rolled. Equipped with two roller holders which allows one labels rolled to be consumed while the other rolled is on standby mode. When the current rolled is over the machine automatically changes to the rolled on standby mode, giving as a result a constant labeling without interruptions.

Furthermore the device has a beacon/siren that activates automatically when one of the labels rolled is empty. The operator can replenish the rolled on the empty roller holder making a splice label reel between the new and the old one in an easy, tidy and efficient way without stopping the labeling head.

It is prepared to different sizes of labels and different liner or tape reel types.

Controlled by PLC with touch screen TFT color 7”, offers a friendly management with the operator, with icons for each setting. Available different user level accounts and complete record of events to meet the standard 21 CFR Part 11 (FDA). There is also a USB port for downloading the Event´s log and to update the software.

PhC ABQCosmetics / Pharma Line / Food, Beverage: ARII-80 NON STOP

Double labeling head ARII-80 NON STOP.

Is a device designed to apply self-adhesive labels with NON-STOP function, reducing the idle time in production line.

Outstanding Features

- Allows continues labeling, without stopping the line to replenish the label rolled.

- Easy splice label reel between the empty and the new rolled.

- Quality control of computerized system according to guidelines given by GAMP5 (ISPE) and 21 CFR Part 11 (FDA).

- Minimum space required.

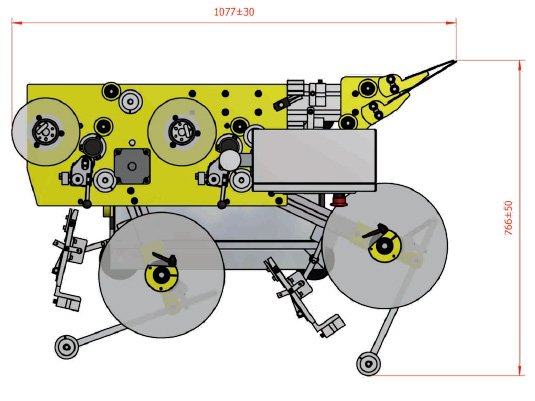

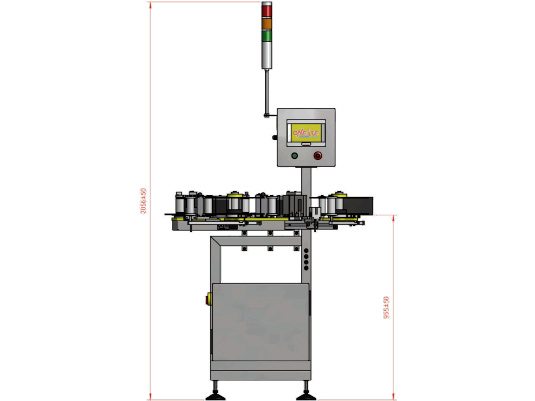

Actual Dimensions

Upper Layout

Front Layout

Technical Data

| Dimensions (mm) - Lenght x Width x Height | 1251 x 811 x 1906 |

| Weight (kg) | 80 |

| Installed Power (KVA) | 0,5 |

| Noise Level (dB (A)) | ≤ 80 |

| Production capacity (packs / minute) * | 400 |

| Speed range (meters/minute) * | 10 - 40 |

| Label sizes range - Height x Width | 25-75 x 15-100 |

| * The specification can change depending on the application. | |

The mentioned characteristics can be modified without prior notice if the Company considers it for manufacturing or operating reasons. Operation voltages can be adaptable to each country or working environment.

Aware of the need to maximize space in the clean rooms in pharmaceutical industry, the size of our machines is one of the main premises at the time of the design of our entire Pharma Line.

GET IN TOUCH! Take advantage of the knowledge of our Sales Team by calling us today on +54 260 442 1956 or from here . We will be happy to help you to come up with the most effective solution for your requirements.