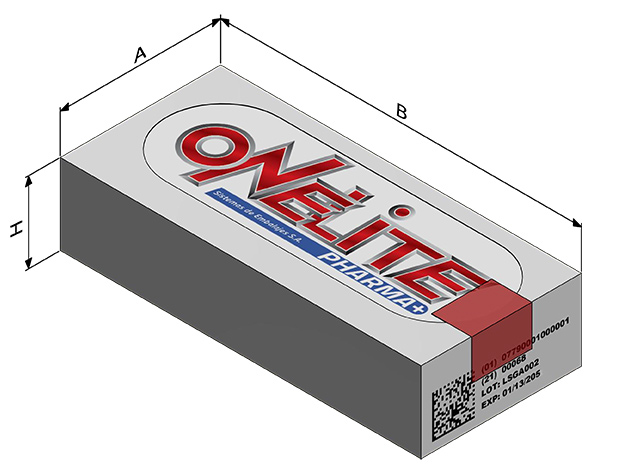

The AR-BOX PLUS is an Automatic linear labelling machine, designed to apply self-adhesive labels, seals or tamper evident for the inviolability of tuck flap cartons, on upper and/or bottom faces of closed boxes. It can reach a maximun output of 400 pcs/min what makes that the machine can fit to the industry with the required flexibility. The labelling machine offer the possibility to host up to 3 labelling heads with clear labels detectors and automatic recovery of missing label.

Simple and quick settings, only by two mechanical adjustments for the boxes´s width and height. Controlled by PLC with touch screen TFT color 7”, allows a friendly management with the operator, with icons for each setting. Login for each user level and complete record of events to meet standard CRF21 Part 11 of the FDA.

Memorized settings on different recipes for easy recall at the time of tagging the same product. Adjustable operating speed by a single parameter, while maintaining the synchronization of the entire machine.

It offered the possibility and space to add printers and data capturer of traceability information for integration with e-Pedigree and serialization systems.

PhC Cosmetics / Pharma Line: AR-BOX Plus

Labelling machine for Tamper Evident AR-BOX PLUS

Automatic linear labelling machine, designed to apply self-adhesive labels, seals or tamper evident. The smaller labelling machine in the marketplace.

Details Gallery

Stepper motors (PAP) that produce greater precision in the displacement of the moving parts of the machine.

Mechanical height and width adjustments to quickly adapt the machine to different case sizes

Ejection system of rejected products with control of product entry into the drawer.

PLC with 7” touchscreen HMI that offers the operator a pleasant handling of the machine

Outstanding Features

- Storage of programs with mechanical and digital setting values, for a quick adaptation to the different case sizes.

- Application of tamper-evident labels in cases with straight or reverse tuck flap.

- Quality control following the guidelines of GAMP 5 (ISPE) and CFR 21 parte 11 (FDA).

- Adjustment of operating speed with a single parameter, maintaining the synchronization of the entire machine.

- Rejection of defective units assured by detection of entrance into the reject drawer.

- Minimum spice required.

- Appropriate safety for the operator and the working environment.

- Generation, restoration and download of system backups.

- Ethernet communication port.

- USB port for software actualization and download of Even Log information.

- Integration with Track and Trace system.

- PLC control system with touchscreen 7” that makes the labelling machine easier to operate.

- Mechanical adjustment in height and width, to quickly adapt to the different case sizes.

- Separator packaging synchronized speed setting.

- Quality Inspector labeling by vision sensors with a pneumatic ejector.

- Quality labeling Inspector by sensors vision with pneumatic ejector.

- Collection box with detector, ejected cases redundant.

- Accountants discarded and accepted on the touch screen products.

- AIRLESS Cases ejector. AR-BOX PLUS can be optionally equipped with electromechanical AIRLESS. Suitable for productions up to 200 cases/minute.

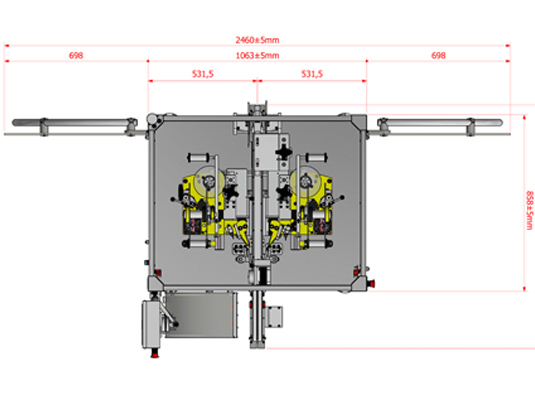

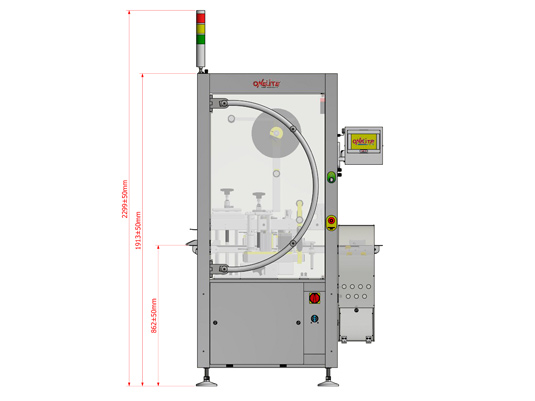

Actual Dimensions

Upper Layout

Side Layout

Technical Data

| Dimensions (mm) - Lenght x Width x Height | 1180 x 1063 x 1900 |

| Weight (kg) | 360 |

| installed Power (KVA) | 2 |

| Air Pressure(bar) | 6 |

| Noise Level (dB (A)) | ≤ 80 |

| Production Capacity (cases / minute) * | 100 - 400 |

| Speed Range (meters/minuteo) * | 10 - 40 |

| Admisible cases (mm) - Width (A) x Height (H) x Lenght (B) | 30-120 x 15-85 x 80-180 |

| Admisible labels (mm) - Height x Width | 25-50 x 15-40 |

| * The maximum production depends on the sizes of the case to be processed. | |

The mentioned characteristics can be modified without prior notice if the Company considers it for manufacturing or operating reasons. Operation voltages can be adaptable to each country or working environment.

Aware of the need to maximize space in the clean rooms in pharmaceutical industry, the size of our machines is one of the main premises at the time of the design of our entire Pharma Line.

GET IN TOUCH! Take advantage of the knowledge of our Sales Team by calling us today on +54 260 442 1956 or from here . We will be happy to help you to come up with the most effective solution for your requirements.